Streamlining Production with cnc turning service

In the modern era of manufacturing, efficiency and precision are more critical than ever. Industries ranging from aerospace to medical technology are under constant pressure to deliver highly accurate components with reduced lead times. One of the most effective ways to achieve this is by utilizing a cnc turning service—a process that blends digital accuracy with mechanical craftsmanship to create finely machined parts.

This article explores the essence of cnc turning service, highlighting its advantages, working principles, applications, and impact across various sectors. Whether you’re a design engineer, procurement specialist, or a small business owner, understanding the capabilities of CNC turning can help you make more informed manufacturing decisions.

What Is cnc turning service?

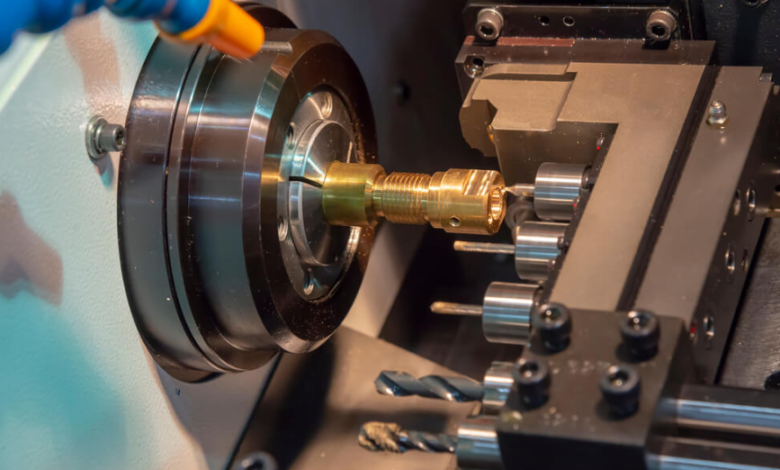

CNC turning, or Computer Numerical Control turning, is a machining process that shapes materials—typically metal or plastic—by rotating them on a spindle while a cutting tool removes excess material to form a desired shape. Unlike manual turning, where a machinist operates the lathe, CNC turning is fully automated. The entire process is governed by a computer program, usually generated from a CAD (Computer-Aided Design) file.

A cnc turning service refers to outsourcing this process to a specialized facility equipped with advanced CNC lathes. These services are invaluable for producing components with tight tolerances, consistent quality, and high repeatability.

How cnc turning service Works

To better understand this process, let’s break it down into a simple analogy. Imagine a sculptor shaping a spinning block of wood using a set of chisels. Now replace the sculptor with a high-speed computer-controlled machine, and the chisels with precision tools made from carbide or diamond-tipped materials.

The basic workflow of a cnc turning service includes:

- Design Phase

Engineers create a digital model using CAD software, detailing every dimension and tolerance. - Programming

The CAD design is translated into G-code—a language CNC machines understand—using CAM (Computer-Aided Manufacturing) software. - Setup

The raw material is clamped into the machine’s chuck. Tools are loaded into the turret, and parameters like spindle speed and feed rate are set. - Turning Operation

The spindle spins the material while the cutting tool precisely shapes it. Secondary features like threads, grooves, and internal bores can be added without repositioning the workpiece. - Finishing and Inspection

Once complete, the part undergoes quality checks, surface finishing, and, if needed, additional treatments like heat-treating or coating.

See also: self loading mixer: The Evolution of Concrete Mixing Technology on Construction Sites

Benefits of cnc turning service

1. Unmatched Precision

CNC turning machines can consistently achieve tight tolerances—often within ±0.01 mm. This level of accuracy is essential for parts used in aerospace engines, surgical instruments, and microelectronics.

2. Speed and Efficiency

Once the machine is programmed, production begins almost immediately. Multiple parts can be produced with minimal human intervention, leading to shorter lead times and increased throughput.

3. Consistent Results

Manual machining is prone to variations, but CNC turning ensures each unit is identical to the next. Whether you need 5 or 5,000 pieces, the results remain consistent.

4. Material Flexibility

A professional CNC turning service can machine a wide range of materials including:

- Aluminum – Lightweight and corrosion-resistant.

- Stainless Steel – Durable and widely used in medical and food processing applications.

- Brass – Easy to machine and great for fittings and connectors.

- Titanium – Used in aerospace and medical implants for its strength-to-weight ratio.

- Plastic Polymers – Ideal for insulation and lightweight mechanical parts.

5. Reduced Waste

Because the cutting paths and tool engagements are carefully programmed, less material is wasted. This not only saves costs but also contributes to a more sustainable operation.

Real-World Applications of cnc turning service

The versatility of CNC turning makes it a go-to solution for many industries. Let’s look at some practical applications:

- Aerospace: Manufacturing turbine blades, bushings, and actuator components that must withstand extreme environments.

- Automotive: Producing pistons, shafts, and threaded fasteners that require high precision.

- Medical: Turning orthopedic screws, dental implants, and precision surgical devices.

- Oil and Gas: Creating parts like pipe fittings and drill collars that must endure high pressure.

- Consumer Electronics: Forming enclosures, connectors, and precision knobs for high-end devices.

Each of these industries relies on cnc turning service to maintain the highest levels of safety and performance.

Choosing the Right cnc turning service Provider

When outsourcing your turning needs, it’s crucial to partner with a trusted provider. Here’s what to consider:

- Machine Capabilities: Ensure they offer multi-axis CNC lathes, live tooling, and bar feeding systems for optimal flexibility.

- Experience: Look for providers with proven expertise in your industry. Familiarity with your material and part requirements will save time and reduce errors.

- Quality Control: Reputable providers implement rigorous inspection processes and may hold certifications such as ISO 9001 or AS9100.

- Lead Time and Support: A good cnc turning service provider offers clear timelines, responsive communication, and engineering support during the design phase.

The Future of cnc turning service

As with many aspects of manufacturing, CNC turning is being revolutionized by technology. Here are some trends shaping the future of this service:

- AI and Machine Learning: Algorithms are being integrated to predict tool wear, optimize machining strategies, and reduce energy consumption.

- Remote Monitoring: Shops can now track machine status and productivity through cloud-based systems, increasing transparency and uptime.

- Sustainability Initiatives: More CNC shops are moving toward eco-friendly coolants, chip recycling, and energy-efficient machines.

- Hybrid Manufacturing: Combining additive manufacturing (3D printing) with turning processes is opening new possibilities for complex part production.

These innovations are not just futuristic—they’re already being adopted by top-tier cnc turning service providers around the world.

Conclusion

In today’s competitive landscape, precision, reliability, and speed are no longer optional—they’re expected. That’s where a cnc turning service comes in. It offers manufacturers the ability to produce high-quality parts with minimal waste and maximum efficiency. From prototype to full production runs, CNC turning enables companies to meet demanding specifications while keeping costs in check.

As technology continues to evolve, so will the capabilities of CNC turning. Businesses that leverage this service today are better positioned to adapt, scale, and succeed tomorrow.